DIY Scaffolding

Circular display system focused on modularity

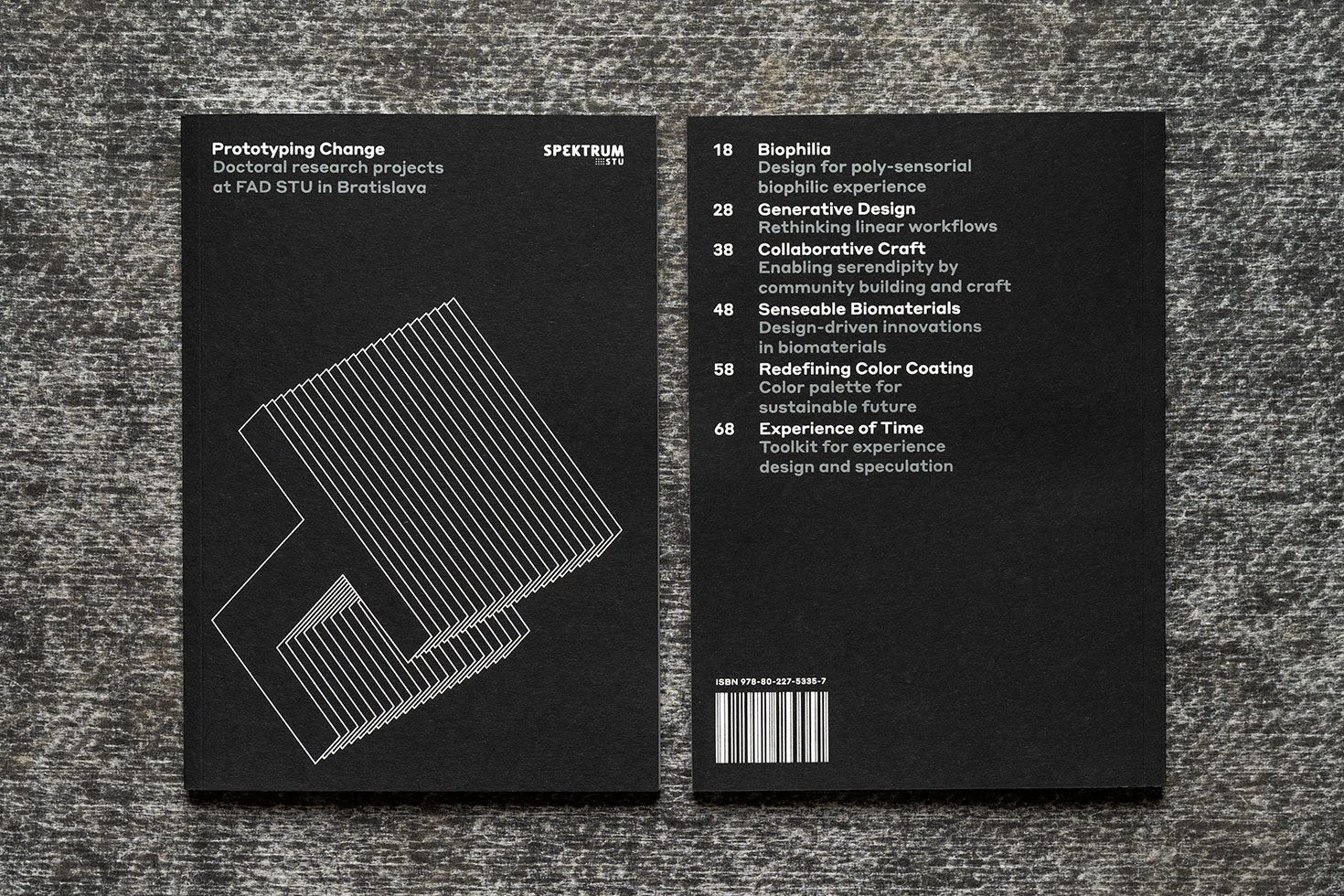

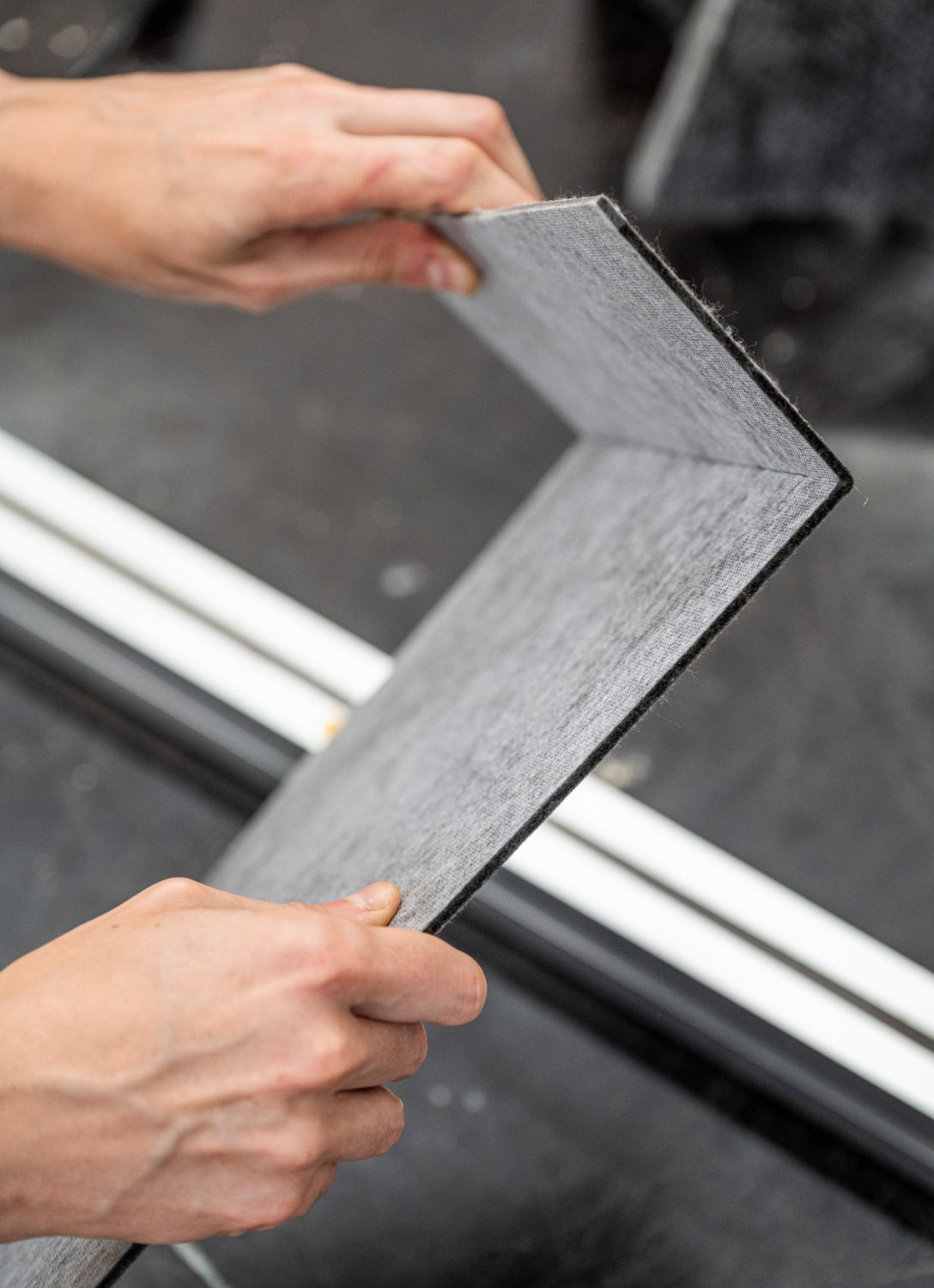

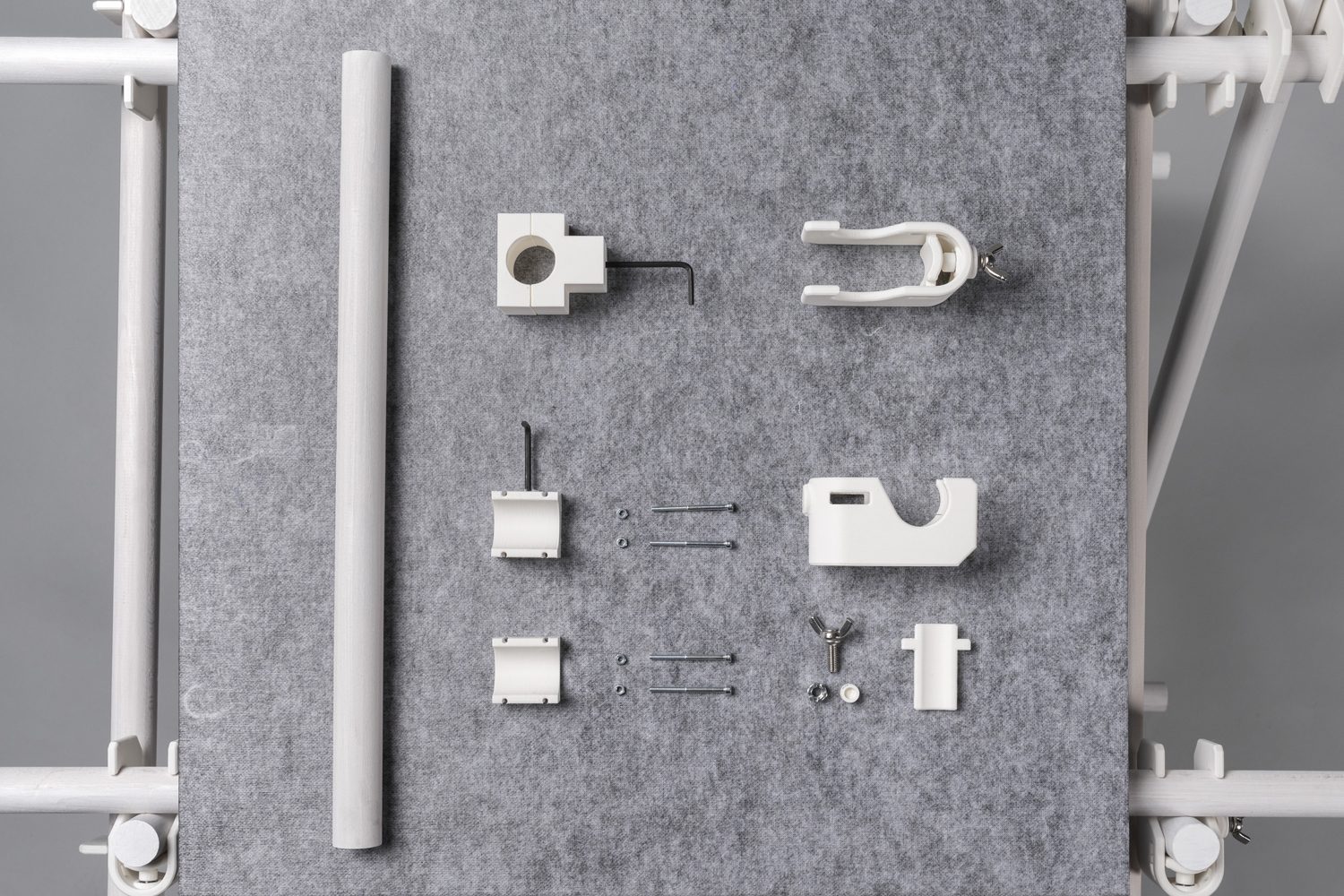

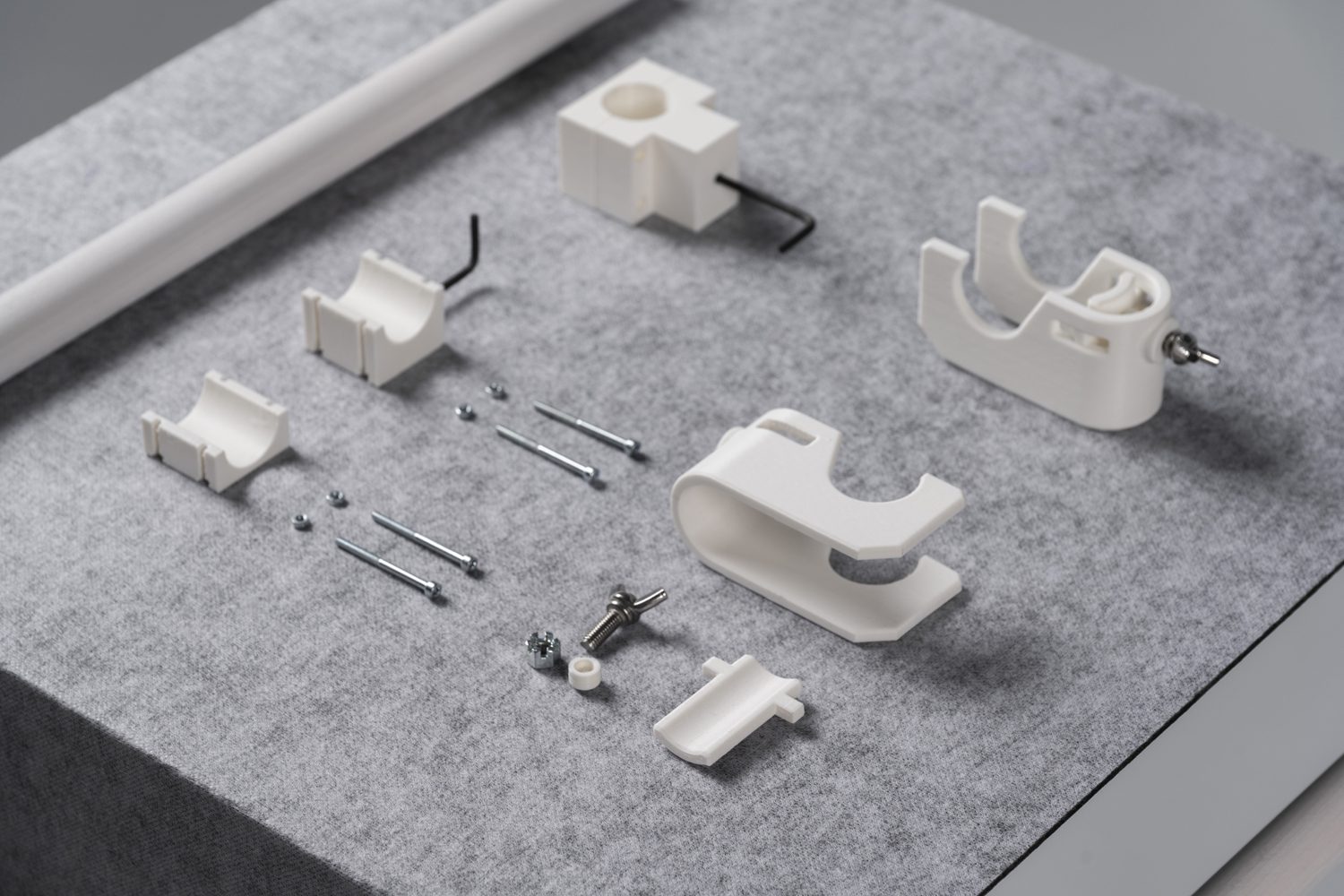

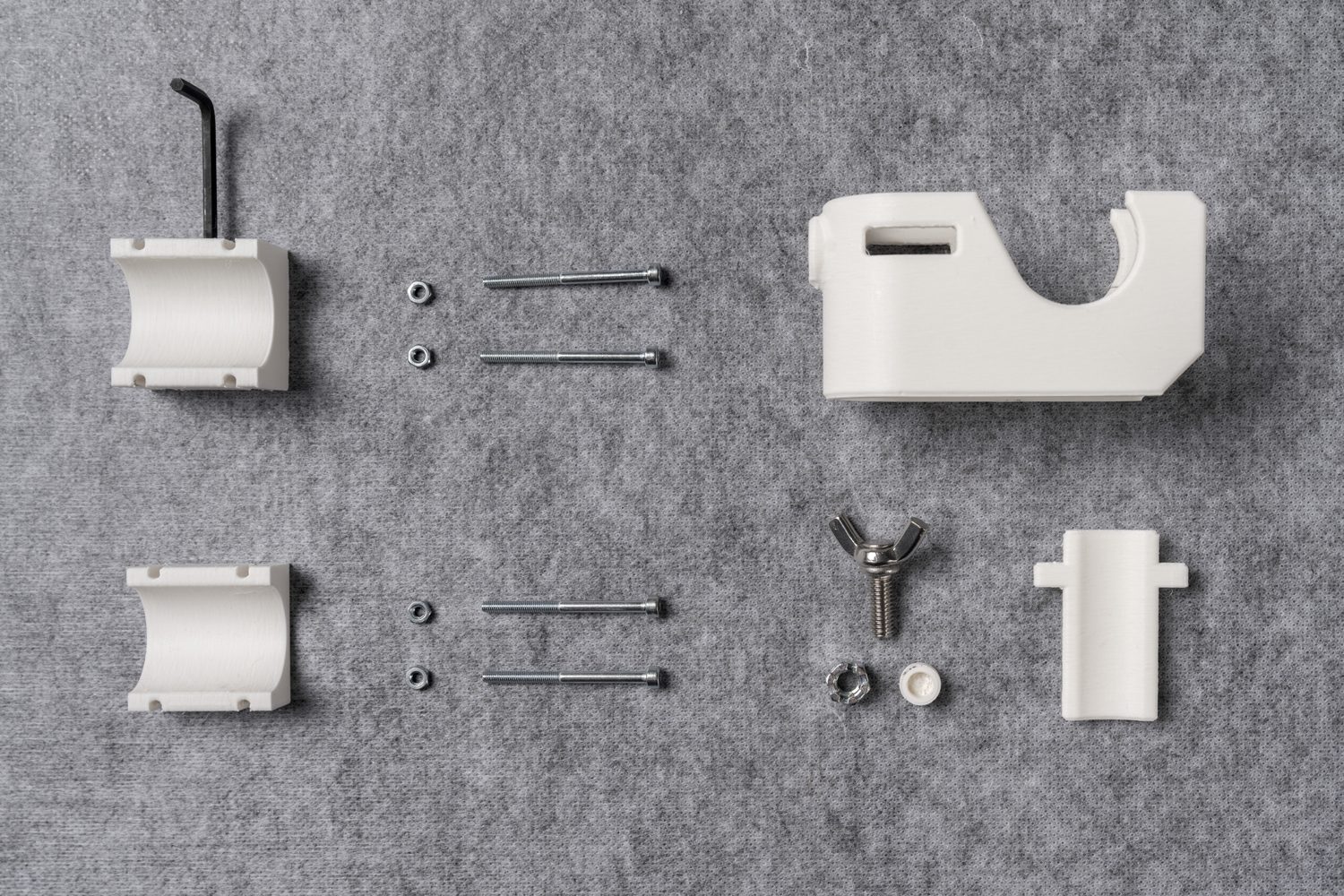

Modular display system used in the DESIGN × SCIENCE exhibition project. The system uses heat-bent spare SymaLITE® boards donated by local automotive suppliers as the main display surface. The construction is made of beech wood rods, connected by custom 3D printed PLA components and standard bolts and nuts inspired by joints used in construction scaffolding. Each part of the exhibition system is replaceable and fully demountable, allowing for future adaptation, reuse, or recycling.

The installation uses SymaLITE® boards provided by Mitsubishi Chemical Group. SymaLITE® is recycled low-weight reinforced thermoplastic used for producing three-dimensional components utilizing low-pressure molding, finding multiple applications in the automotive industry such as car undershields, engine and gearbox covers, etc.

While the material life cycle is designed to reuse the scrap edge trims, the production cycles exceptionally leave local subcontractors with extra boards in stock with minor imperfections that fall outside of the acceptable production tolerance limits. Trying to avoid unnecessary recycling of unused industrial intermediate products, the authors of the exhibition display design – František Dorko and Martin Sombathy – were looking for possible applications in small series production.

Links:

- MORE ABOUT THE PROJECT [.pdf]

Photo:

Adam Šakový, 2023 [studio photos]

Petra Hurai, 2023 [Designblok installation]

Read more

Read more

Partners

People

Martin Sombathy

Exhibition Design

František Dorko

Exhibition Design

Michala Lipková

Exhibition Curator

Petra Hurai

Co-production

Peter Chmela

Graphic Design